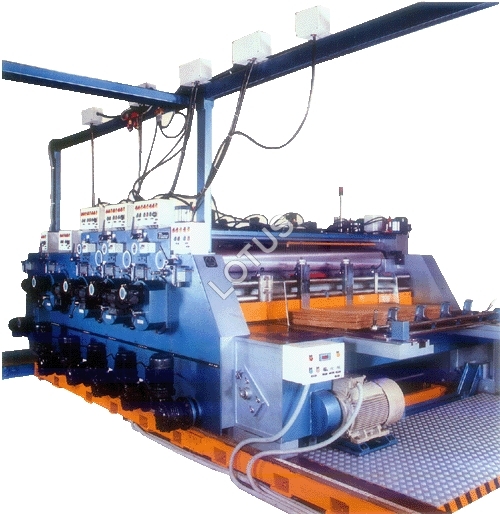

Product Description

All the units are placed on railing bace they can be

separated from each other by motorised operation.

| FEEDING UNIT |

| | Kick feeding with vaccum assit. | | | Two feeding rollers with two side guides | | | Adjustable sheet stopping brackets to ensure feeding of one sheet at a time. | | | Sheet resting brackets to pile the sheets. | |

|

| PRINTING UNIT |

| | Top printing system, easy to view. | | | Dust guards are provided the anilox and the doctor rolls. | | | Ink rollers with idiling devices prevent the ink from drying while the machine is not in operation | | | Printing units with motorised registration systems. | |

|

| CREASER SLOTTER UNIT |

| | 4 sets creasing heads and 2 sets trimming heads. | | | 3 sets slotting heads and 1 set corner head. | | | Shifting of heads is done manually. | | | Slot up and down adjustment is motorised. | |

|

| DIE CUTTING UNIT |

| | Top cylinder is covered with anvil covers and the bottom cylinder is provided to fix the rotary Die. | | | Mechanical transmission geared motor to move the top cylinder laterally for equal wear & tear of the blanket. | | | The forward and backward adjustment of the die cutting cylinder is motorised. | | | Two sheet gripper rollers to carry the sheets towards the delivery conveyor. | |